ERP

3 MYSTIC LETTERS forming the acronym of “Enterprise Resource Planning” or more specifically a software with the help of which we can manage enterprises – ranging from small companies to large corporations in their entirety.

THE REALITY, however, shows that the modern ERP software is COMPLICATED to use, FRAGMENTED, EXPENSIVE, and quite often perceived as an UNJUSTIFIABLE INVESTMENT for the companies due to the lack of clear evidence showing that the implementation of this type of a system directly reflects into better business results.

THE REALITY, however, shows that the modern ERP software is COMPLICATED to use, FRAGMENTED, EXPENSIVE, and quite often perceived as an UNJUSTIFIABLE INVESTMENT for the companies due to the lack of clear evidence showing that the implementation of this type of a system directly reflects into business results.

EXAMPLES of unjustifiable investments

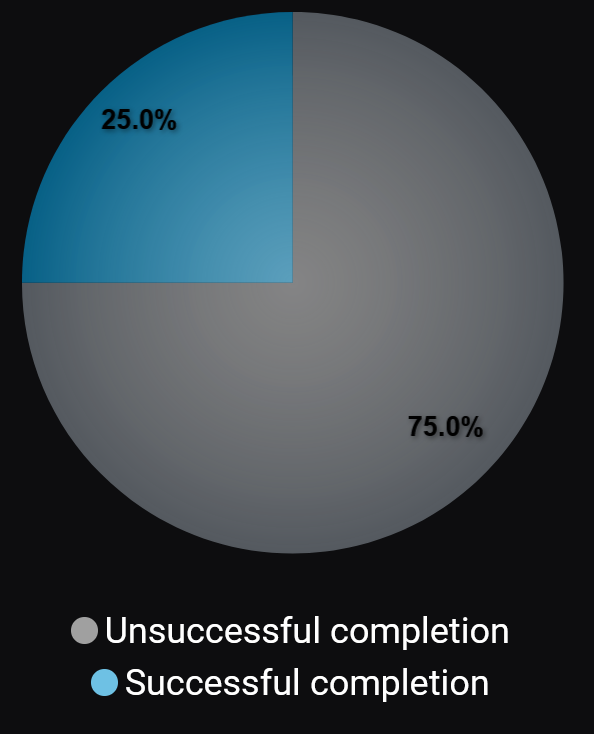

According to GARTNER (a leading American consulting company that first defined the concept of the ERP system), between 55% and 75% of the ERP implementation projects fail.

According to leading consultants, the main reason for this type of high percentage of failure appears to be…

„The lack of organizational culture in the companies and the willingness for change of the management team“.

THE PROBLEM

ALTHOUGH THIS INDEED APPEARS AS A PROBLEM, IT IS FAR FROM BEING THE MAIN PROBLEM!

THE MAIN PROBLEM is that the working constructs of today’s ERP systems are flawed due to the lack of a clear holistic model for the principal setup and way of functioning of the industrial enterprise embedded in the ERP constructs.

As a result of this deficiency, neither the developers, nor the consultants, not even the consumers can clearly define how this software can resolve the multitude of various business challenges.

This causes the development of various modules and applications from which fragmentary solutions are being offered on an individual basis for each client. This, however, has low instrumental effectiveness for the positive development of the enterprise.

If we draw an analogy with the medieval medicine – in the absence of an anatomical and physiological model of the human body (holistic model of the industrial enterprise), the doctors (ERP developers and implementation consultants) were not able to carry out empirically founded treatment (holistic ERP solution) to the diseases (business cases) of patients (consumers).

And here comes the first HOLISTIC SOLUTION in the History of knowledge development for digital transformation!

Institute for Systemic Economic Engineering

develops and successfully experiments a holistic ERP system based on new knowledge for managing the economy of industrial enterprises of higher quality – the first holistic business model ontology.

After more than 100 years and 3 global waves in the development of knowledge of digital transformation

It involves the creation, development, and dissemination of knowledge of operational modeling of processes in the enterprise.

1856 - 1915

It involves the creation, development, and dissemination of knowledge of production management focused on quality.

1900 - 1993

It involves the creation, development, and dissemination of knowledge of computer-integrated modeling of the sales, production, and supply processes.

1930 - 1983

It involves the creation, development, and dissemination of knowledge of the principle setup and way of functioning of the industrial enterprise and a new generation holistic ERP system.

I ENGINEERING WAVE

It involves the creation, development, and dissemination of knowledge of operational modeling of processes in the enterprise.

Frederick Taylor

1856 - 1915

II ENGINEERING WAVE

It involves the creation, development, and dissemination of knowledge of production management focused on quality.

William Deming

1900 - 1993

III ENGINEERING WAVE

It involves the creation, development, and dissemination of knowledge of computer-integrated modeling of the sales, production, and supply processes.

Oliver Wight

1930 - 1983

IV ENGINEERING WAVE

It involves the creation, development, and dissemination of knowledge of the principle setup and way of functioning of the industrial enterprise and a new generation holistic ERP system.

1997 - present

ISEE has successfully developed knowledge about managing all enterprise processes at never before seen level.

hERP

Thanks to the new quality of scientific knowledge of business model ontology , ISEE successfully created a holistic ERP system that manages the enterprise as a systemic object and subject simultaneously by managing the cognitions accumulated in the enterprise

The holistic ERP system is designed and based on a holistic business model ontology – a universally applicable knowledge of the principle setup and way of functioning of the industrial enterprise – the unique discovery made by ISEE JSC.

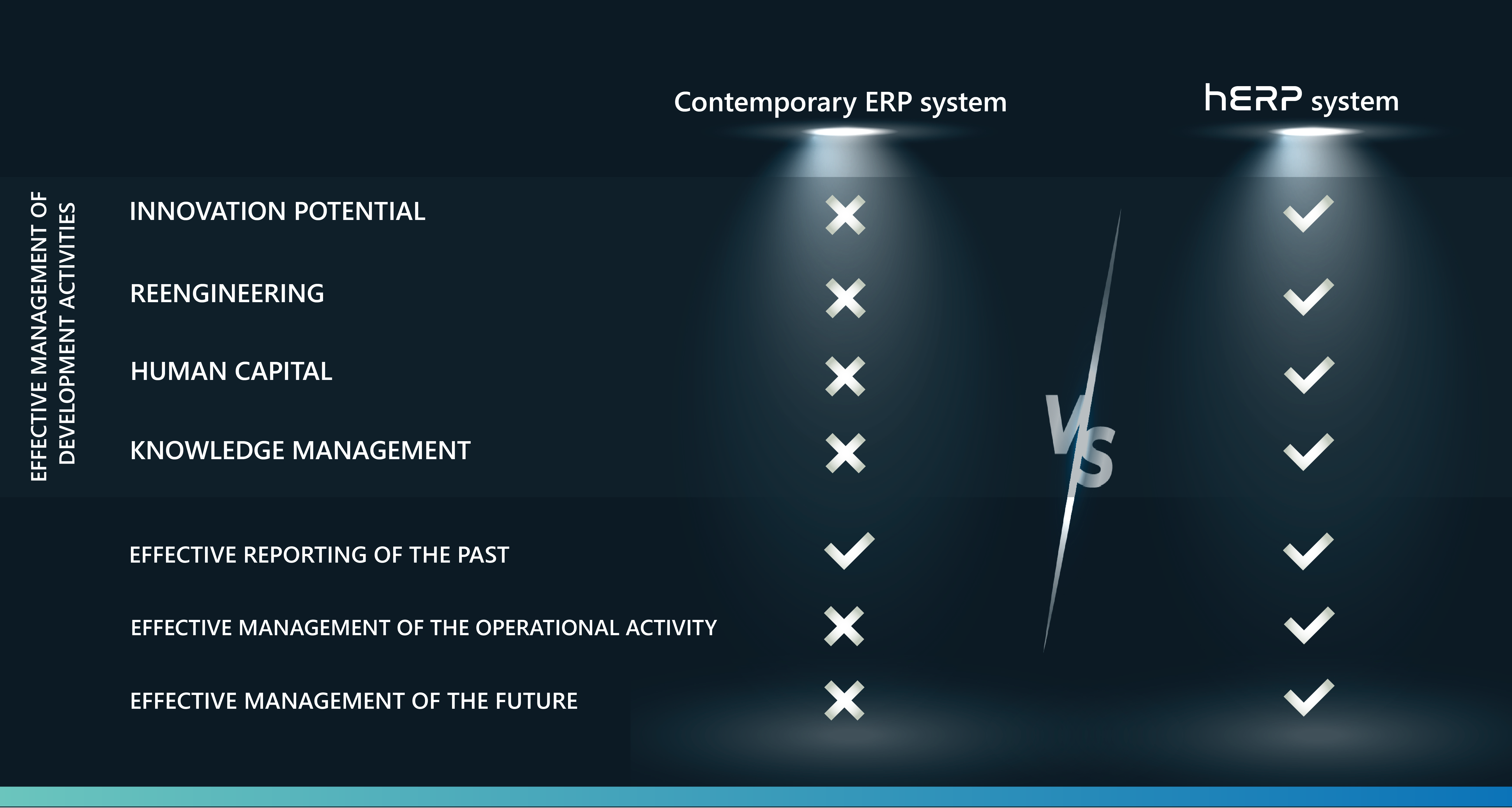

COMPARISON AMONG THE CONTEMPORARY ERP SYSTEMS AND hERP SYSTEMS AS AN INSTRUMENT FOR EFFECTIVE MANAGEMENT OF THE INDUSTRIAL ENTERPRISE

The hERP system enables the engineering of new enterprises by modelling their technological environment (a symbiosis between the technical and organizational environment). This enables an already existing enterprise to engineer and launch into production a new or not yet implemented product (good or service), or to implement new technological processes.

The hERP system enables to carry out a radical restructuring of the technological environment of the enterprise (a symbiosis of the technological and organizational environment) in order to achieve a significant improvement of the business result and a substantial increase in the efficiency.

The hERP system allows for defining of the collective responsibility of the enterprise, through which defining the individual responsibility becomes possible, and from here — the development of effective job description, based on which, human capital management and development becomes possible for effective realization of the enterprise ambitions.

The hERP system allows for a systematic and objective process of formation, storage, distribution and utilization of intellectual capital indispensable for the functioning of any given enterprise, hierarchically subdivided into (1) Cognition for industrial results, (2) Implementational cognition, (3) Principal cognition, (4) Functional cognition, (5) Fundamental cognition.

The hERP system gives systematic, effective, and complete reports of past conditions of the enterprise, including past periods, immediately before the present moment. This comprehensive coverage enables for precise tracing of activities that took place at each, and every single part of the enterprise and this information is available at any given time.

The hERP system allows for the effective and interconnected management of the business processes related to Sales, Production, Supply and Financing (Working capital flow). The management efficiency by the hERP system is consistently high, irrespective of the complexity of the technological environment, size of nomenclature of the managed objects, and volume of the production batch. Working capital flow data and variables are always relevant and accessible in real-time.

The hERP system provides all the necessary data on the condition and state of the enterprise, both from past periods and from the present moment, as well as for the future projected periods. Based on these facts the system allows to create and execute highly effective projects for future economic development of the enterprise according to the stakeholders’ ambitions.

CONDUCTED RESEARCHES SHOWING THE hERP ADVANTAGES

During the 20 years of ISEE JSC existence, a series of research and experiments have been conducted proving the practical superiority of the hERP technology over the global alternatives. Some of the research and experiments include:

Implementation site: Hydraulic Elements and Systems PLC, Yambol, Bulgaria.

In the period between 2009 and 2010, in the short span of 18 months, two engineers without any prior experience in plant design or knowledge of the so-called Lean Manufacturing theory, but highly proficient in the ISEE IT solution and its cognitive platforms, developed and rolled out a system for SMED (Single-Minute Exchange of Dies — Quick setup) and lean manufacturing in two sections comprising a total of approximately 40 workplaces with computer numerical controlled (CNC) machines.

Conclusions:

Following SMED the productivity of the workplaces in question increased between 5 and 10 times. Minimal costs were incurred. A personnel training programme was also developed.

By way of comparison, the development and roll out of such a system on a similar scale, within a plant owned by a large Western company, took approximately 6 years, meaning that significantly greater human and financial resources were needed.

Implementation site: Hydraulic Elements and Systems PLC, Yambol, Bulgaria

The experiment took place immediately after the global economic crisis set in 2009. During the campaign, which ran from the spring of 2010 until the summer of 2011, more than 70 % of all workplaces were restructured and relocated.

Conclusions:

The experiment was conducted in a highly expeditious manner, without any delay or suspension of industrial processes. On the contrary, over the course of the reengineering process, production marked an increase in terms of both volume and nomenclature. This increase was more than twofold. The research team failed to find a precedent where industrial reengineering had ever been conducted, by any party, that was comparable in terms of investment indicators to the performance achieved in this experiment, which would not have been possible without the ERP system designed and developed by ISEE JSC.

Implementation site: Battery plant Tungstone, Ryazan, Russia

After studying the functional constructs of hERP, a young Russian management team achieved the following results in a battery plant in Russia over a time-span of 3 years:

At the end of 2009, the plant has a headcount of 176 employees, who manufactured up to 7 000 car batteries a month worth EUR 190 000 or approximately EUR 2.3 million per year.

At the end of 2012, the plant had a headcount of 196 employees, who manufactured up to 34 000 car batteries a month worth EUR 980 000 or approximately EUR 12 million per year. This means that labor productivity increased more than four times and sales increased almost five and a half times. It is important to note that all investments made over the three-year period came up to less than EUR 1 (one) million.

The results of the comparative evaluations conducted by three independent working groups (representatives of business universities, technical universities and practicing engineers) conclusively demonstrated that the hERP system is vastly superior to all other solutions, including those most renowned (SAP, Oracle, Microsoft, Infor).

“Developed under the influence of the currently dominant management models, the evaluated IT products manifested the same weakness. As regards the reporting, financial and accounting practice, creation of information flows, investment and state administration needs, resource and expenditure planning they may be assessed as “good”. Yet, they do not demonstrate an overall insight into the management of the business unit, whereas the management of the technological potential goes beyond discussion. The lack of clearly formulated notion, the lack of a single and empirically tested concept system as well as the lack of understanding of the fundamental essence of the Business Unit makes them a secondary “Accounting Software”. This opinion results from the fact that the teams make a continuous referral to accounting records, documents and principles when they demonstrate their so-called business unit management software.

In conclusion, after a series of observations, research and analysis of the achievements of the contemporary management theory and practice, we can state that the proposed System Knowledge Management Model is based on the concept of “creation” and search for manageability of the technological potential development, as proposed by the contractor under the framework contract with “HES” PLC, as well as the IT product developed and implemented thereof, are conceptually completed, terminologically clear, empirically relevant, and subject to the obvious structural components and processes in the Business Unit functioning. We believe that from the point of view of the management theory and practice, they demonstrate significant and innovative conceptually clear paradigms, which bring them on a higher level as compared to the familiar and commonly implemented solutions at present.”

Implementation site: Hydraulic Elements and Systems PLC, Yambol, Bulgaria and M+S Hydraulic PLC, Kazanlak, Bulgaria

Five young mechanical engineers without any prior experience in plant design but thoroughly versed in the ISEE JSC’s ERP system, managed to build and back up the operation of an expanded technological environment at both plants in order to introduce highly innovative (for Bulgaria) production of axial piston hydraulic pumps and motors. They did so for the same amount of time and money that foreign consulting companies required to simply update product documentation.

Conclusions:

Under their leadership, four workers without any specialist experience took 9 months to learn a range of high-tech processes, which usually require 25 to 30 highly skilled specialists trained at global market leader companies.

The products manufactured were sent to a renowned specialist laboratory in Germany. Experts there were amazed that products with such appearance and quality could have been designed and manufactured in Bulgaria.

The conclusion of a team from Information Technologies and the Future of the Economic Science (ITFES) Foundation, based on a number of presentations of leading ERP software developers, showed that the systems they are creating continued to be fragmented, module-based and none of them is a bearer of a universal model of the industrial enterprise

Implementation site: Unitraf JSC Sokolovo, Bulgaria

In 2021, within 14 months, a 2-person management team began the implementation of the holistic business model ontology in a 50-person transformer company. It is important to note that within this experiment, only the knowledge is implemented without the holistic ERP system. The results are as follows: over the 14 months, the total turnover increased by 50%, the value added increased by 127%, the average salary increased by 50%, and the profit increased by 357%.

The conclusion of the ITFES Foundation team based on the numerous presentations of leading ERP software manufacturers is that the so far created systems are still fragmented and module-oriented, and none of them is or can serve as a universal model of the industrial enterprise.

The direct juxtaposition between the hERP system, developed by ISEE, and the leading ERP system brands show that the DEVELOPED HOLISTIC TECHNOLOGY, unlike all other fragmented ERP systems, ALLOWS FOR STRATEGIC MANAGEMENT OF THE ENTERPRISE in a form of effective development management, as well as effective operational management.

ISEE JSC possesses a disruptive technology in the field of managerial modelling of the economy of enterprises as well as a team who can further develop it.

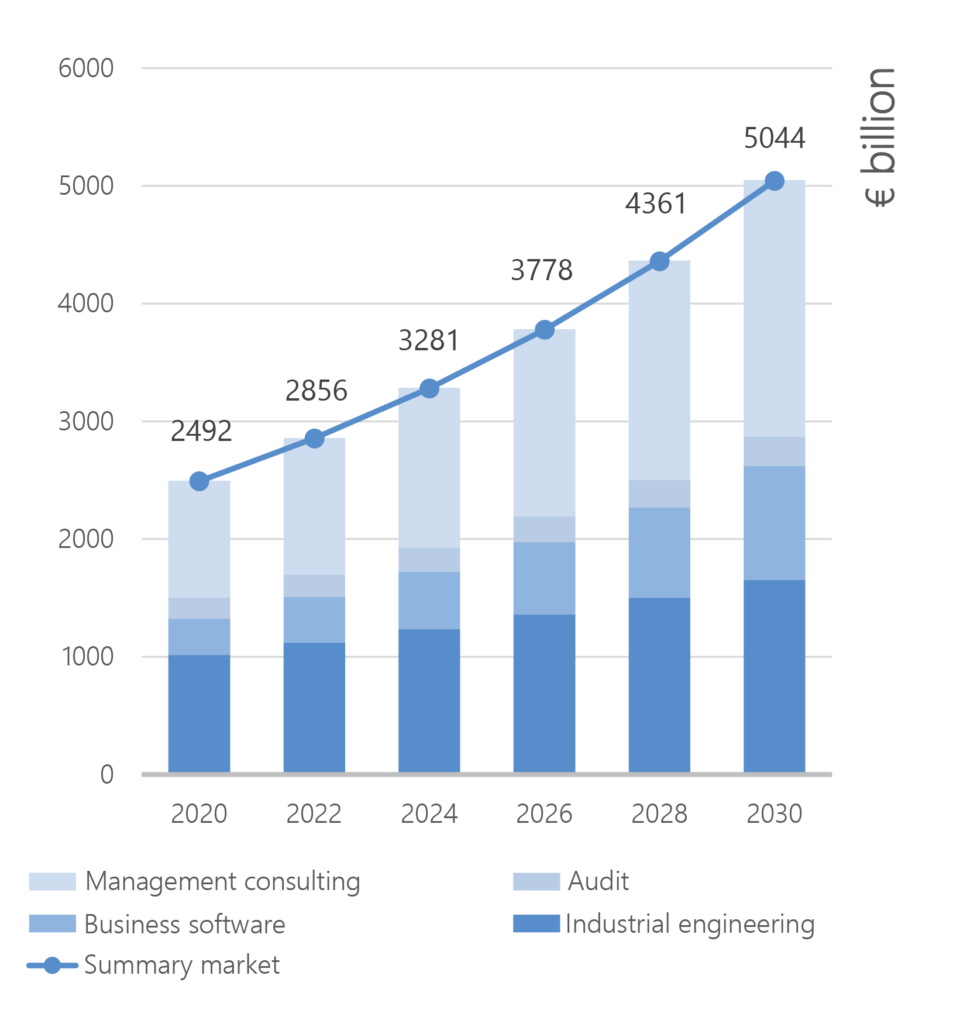

A disruptive technology as this one can lead to redistribution of the global market of knowledge for managerial modelling of the industrial economy. Products in the form of business software, business consulting, business auditing, as well as industrial engineering and reengineering. These are markets that strike above 2.5 trillion EUR annually as of 2021.

Due to the inability of large ERP developers to internally overcome their own deficit of knowledge in order to create a holistic solution, they regularly seek resolutions OUTSIDE by purchasing innovative companies in the area of ERP.

SAP

Acquisition date: Jan 2021-

Acquired company:

Signavio -

Specialty:

Collaborative Business Process Design, Management and Analysis -

Country:

Germany

SAP

Acquisition date: Nov 2018-

Acquired company:

Qualtrics -

Specialty:

Collect, Manage, act on Experience data

-

Country:

USA

SAP

Acquisition date: Nov 2018-

Acquired company:

Contextor -

Specialty:

Robotic Process Automation

-

Country:

France

SAP

Acquisition date: Jan 2018-

Acquired company:

CallidusCloud -

Specialty:

Sales Performance Management Tool

-

Country:

USA

SAP

Acquisition date: Sept 2014-

Acquired company:

ConcurTechnologies -

Specialty:

Travel and Expense Management

-

Country:

USA

Oracle

Acquisition date: Dec 2017-

Acquired company:

Aconex -

Specialty:

SaaS-based construction project management

-

Country:

Australia

Oracle

Acquisition date: Jul 2016-

Acquired company:

NetSuite -

Specialty:

Cloud/SaaS-based Enterprise Resource Planning (ERP) software

-

Country:

USA

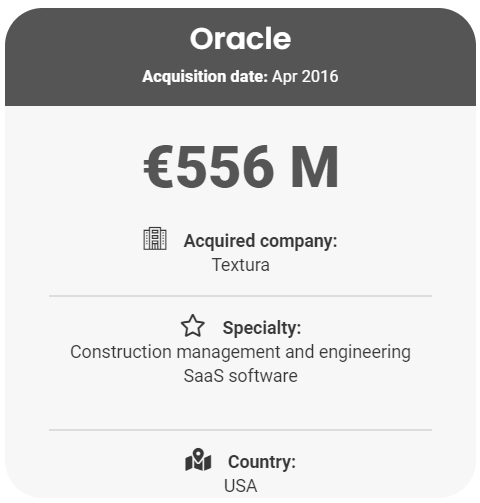

Oracle

Acquisition date: Apr 2016-

Acquired company:

Textura -

Specialty:

Construction management and engineering SaaS software

-

Country:

USA

Oracle

Acquisition date: Dec 2012-

Acquired company:

Eloqua -

Specialty:

Marketing Automation platform for managing sales and marketing leads across an enterprise -

Country:

USA

Oracle

Acquisition date: Feb 2012-

Acquired company:

Taleo -

Specialty:

Talent Management Software

-

Country:

USA

Despite the huge investments made by SAP and ORACLE, they still CANNOT go beyond the modular principle of their ERP systems to propose a new, radically different and holistic solution to their customers, as they continue investing for the purpose

The purchase of the company Signavio— a developer of a module for improving the business processes — for the amount of €1 billion in January 2021, together with the pompous release of RISE with SAP (yet another attempt for “one ERP system to replace them all”) proves this fact.

How much would big ERP developers be willing to invest in a company that has engineered a new type of ERP software with proven higher functionality compared to all existing ERPs?

Software that allows for the complete management of an enterprise, facilitates the prompt reengineering of large enterprises, and enables the creation of new enterprises.

How much would big ERP developers be willing to invest in a company that has engineered a new type of ERP software with proven higher functionality compared to all existing ERPs?

Software that allows for the complete management of an enterprise, facilitates the prompt reengineering of large enterprises, and enables the creation of new enterprises.

ISEE INVESTMETNTS

ISEE JSC PLANS TO SELL A MAJORITY SHARE (67% TO 70%) TO A STRATEGIC INVESTOR (SUCH AS SAP, ORACLE, GOOGLE, MICROSOFT, TESLA AMAZON ETC.) for 2 BILLION EUR IN 2027.

TO PUT THIS INTO PERSPECTIVE, SAP AND ORACLE HAVE MADE RECENT ACQUISITIONS OF TECHNOLOGICAL COMPANIES THAT AMOUNTED TO AN AVERAGE OF 3 BILLION EUR. HOWEVER, THESE ACQUISITIONS TYPICALLY INVOLVED PURCHASING FRAGMENTS AND PIECES OF SOFTWARE SYSTEMS RATHER THAN A COMPLETE, HOLISTIC ERP SYSTEM.

THE LAST ACQUISITION OF A COMPLETE ERP SYSTEM (NETSUITE), ALBEIT CONVENTIONAL, WAS CARRIED OUT IN 2016 FOR 8 BILLION EUR BY ORACLE.

FIRST ROUND

2017-2021

40 MILLION EUR.

SECOND ROUND

NECESSITY FOR ADDITIONAL INVESTMENTS

2021-2027

To enable the development of ISEE to the required level for such a sale, a second-round for supplementary funding is currently underway. Тhe required investment is 10 MILLION EUR FOR 10% EQUITY.

THIRD ROUND

SALE TO A STRATEGIC INVESTOR

2027

The achievements of ISEE JSC, in the form of intellectual property and the team behind it, will be offered to a world leading corporation for at least 2 BILLION EUR.

To enable the development of ISEE to the required level for such a sale, a second-round for supplementary funding is currently underway. Тhe required investment is

10 MILLION EUR FOR 10% EQUITY.

The achievements of ISEE JSC, in the form of intellectual property and the team behind it, will be offered to a world leading corporation for at least 2 BILLION EUR.

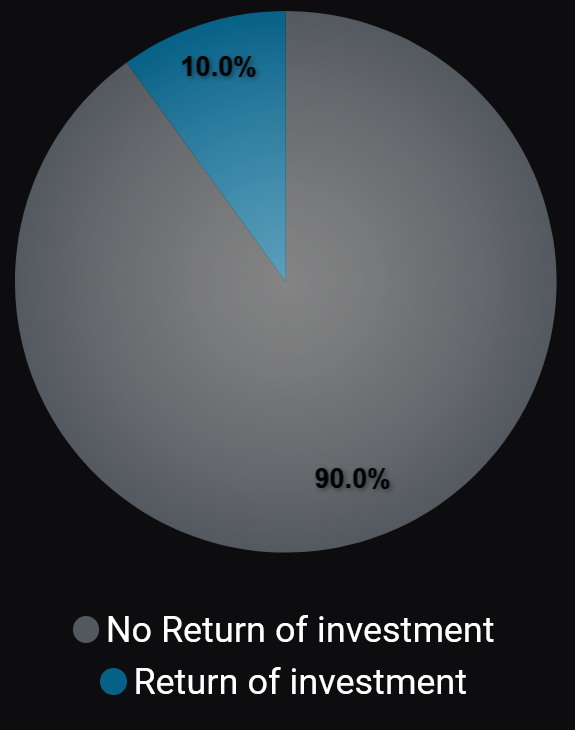

AT THE FIRST AND SECOND ROUNDS, ALL INVESTORS WILL RECEIVE A RETURN OF THEIR INVESTMENT BY 2027, WHEN THE EVENT OF SELLING THE MAJORITY STAKE IN ISEE JSC IS FOR APPROXIMATELY

€2 BILLION

THE TEAM

Petar Bachvarov

Founder

Inventor and patent-holder of a top-down construction method technology used in the construction of the Hemus highway viaducts, Director of numerous machinery companies, including Spartak JSC and HES JSC, Inventor and ideologist of the holistic business model ontology and the holistic ERP system

Anna Videva

Founder

Co-founder of ISEE JSC and co-author of the theory and terminology of the Business model ontology, technological architect of the holistic ERP system.

Trifon

Stefanov

Management team

CEO

Momchil

Denev

Management team

Member of the Board of Directors

Ventsislav

Karaivanov

Development team

Leading Software Architect

Lyubomir

Tonchev

Development team

Leading Software Architect

Martin

Petrov

Development team

Engineer

NEWS